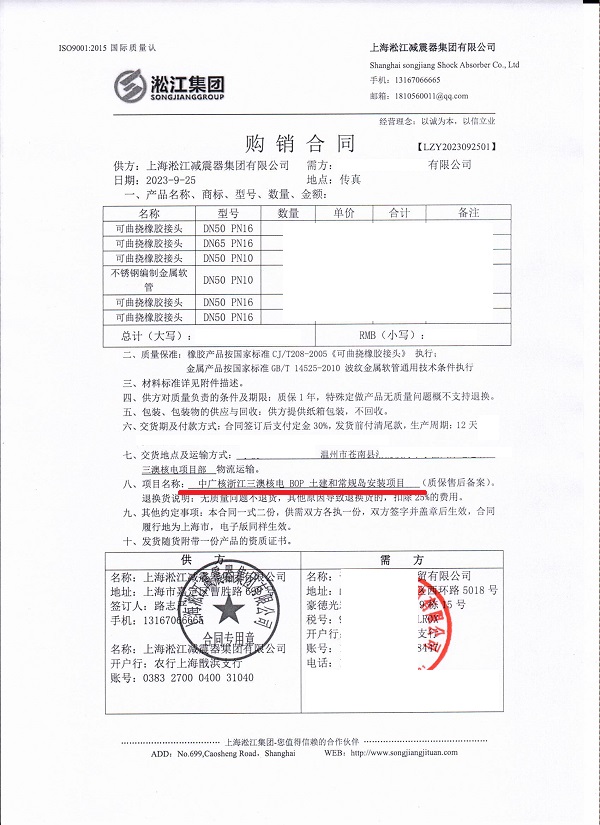

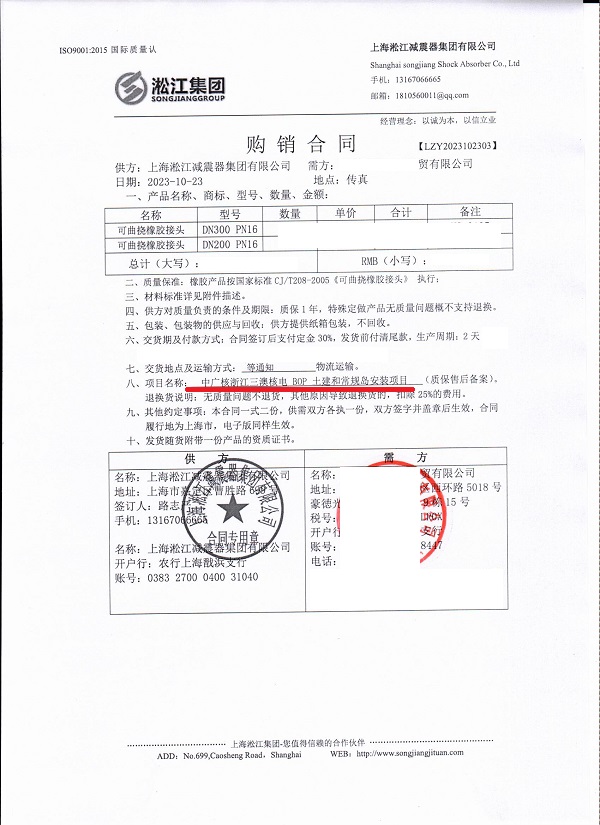

As a national key energy project, the CGN Zhejiang San’ao Nuclear Power Project utilizes China’s independently developed third-generation nuclear power technology, “Hualong One,” with a design lifespan of 60 years. In such a high-standard project, Shanghai Songjiang Group supplied customized rubber joints to support the BOP civil engineering and conventional island installation.

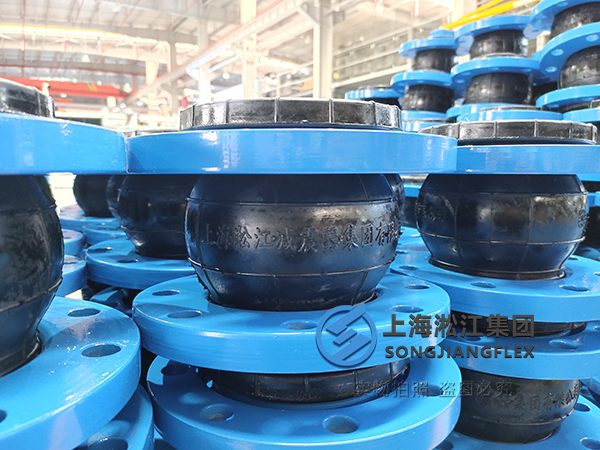

The primary function of rubber joints is to absorb vibrations, reduce noise, and compensate for thermal expansion and contraction in pipeline systems. Especially in nuclear power plants, the complex equipment environment demands equipment with high safety and durability. The rubber joints provided by Songjiang Group for this project not only met the technical standards required by the nuclear power plant in terms of heat resistance and corrosion protection but were also optimized for the project’s specific engineering needs, ensuring long-term stable operation in high-temperature, high-pressure environments.

The rubber joints play a critical role in the nuclear power plant’s piping system. This collaboration provided Shanghai Songjiang Group with an opportunity to showcase its technological capabilities and further solidify its position in domestic and international nuclear power projects.