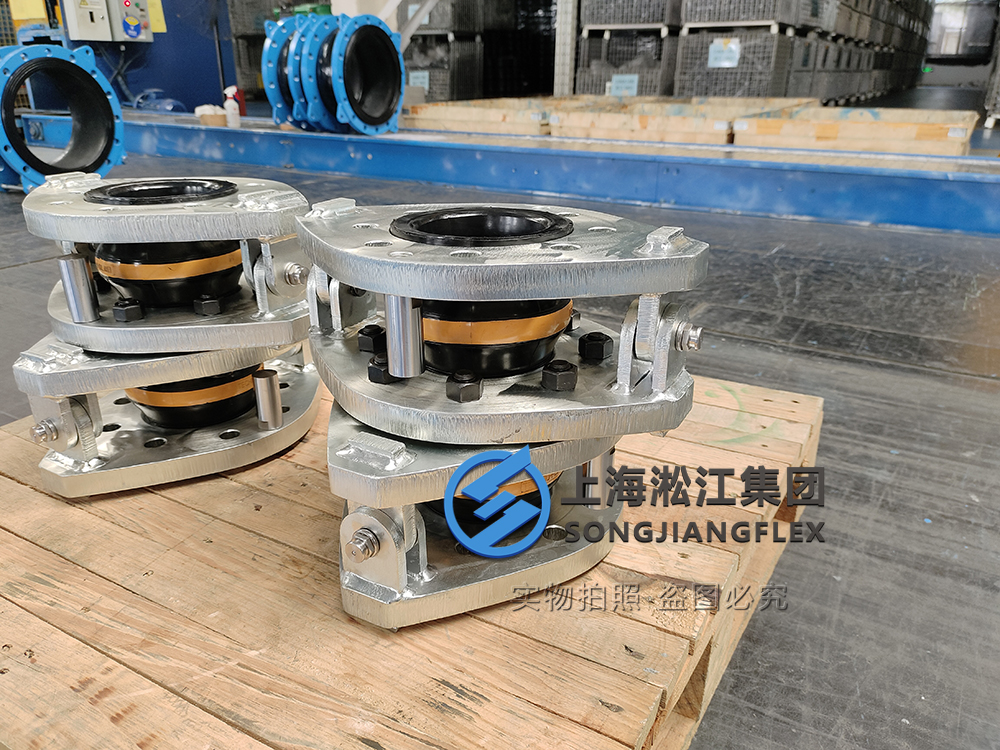

An oil-resistant rubber expansion joint is a critical component used to absorb vibration and thermal expansion in pipelines and machinery. It is designed to withstand the damaging effects of oil exposure, making it perfect for industrial systems where oil is present.

These joints are made from rubber compounds specially engineered to resist degradation from oil, providing long-term durability and effective performance in demanding environments.

What are the primary uses of oil-resistant rubber expansion joints?

Oil-resistant rubber expansion joints are commonly used in various industrial sectors, including the petroleum, chemical, and manufacturing industries. They are often found in systems that transport oil, fuel, or other hydrocarbon-based liquids.

These expansion joints are essential in systems where oil and heat exposure could cause damage to standard materials. They help to maintain system integrity by accommodating the expansion and contraction caused by temperature fluctuations, preventing leaks, and reducing vibrations.

For example, in the petroleum industry, these joints are used in pipelines that transport crude oil or refined products. Their oil resistance ensures that the rubber won’t degrade over time, even when in constant contact with oil.

How does an oil-resistant rubber expansion joint compare to a regular rubber expansion joint?

While both oil-resistant rubber expansion joints and regular rubber expansion joints serve the same primary function of absorbing vibration and movement, the key difference lies in their material composition. Oil-resistant rubber expansion joints are specifically formulated to handle oil-based liquids, while regular joints may deteriorate when exposed to oils.

Oil-resistant rubber expansion joints provide superior longevity in environments where exposure to oil and hydrocarbons is frequent. Regular rubber expansion joints, on the other hand, can become brittle, crack, or degrade over time when in contact with oils and solvents.

By using oil-resistant materials, the joints retain their flexibility, elasticity, and durability, even under challenging operating conditions. This makes them the preferred choice for applications in industries such as oil refineries, chemical plants, and automotive manufacturing.

What are the benefits of using oil-resistant rubber expansion joints?

The oil-resistant rubber expansion joint offers several significant advantages over standard expansion joints. These benefits include:

-

Superior Oil Resistance: They are formulated to withstand exposure to oils, fuels, and other hydrocarbon-based substances without degrading.

-

Enhanced Durability: The specialized material ensures that the joints last longer, even in harsh environments.

-

Improved Vibration Absorption: These expansion joints help to reduce noise and vibration in pipelines and machinery, improving overall system performance.

-

Flexibility: They are flexible and able to accommodate movement caused by thermal expansion or shifts in the system, preventing damage to pipes or equipment.

By using oil-resistant rubber expansion joints, companies can improve system reliability, reduce maintenance costs, and extend the lifespan of their equipment. This makes them an essential component for industries where oil exposure is a common occurrence.

How to properly maintain oil-resistant rubber expansion joints?

Maintaining oil-resistant rubber expansion joints is essential to ensure that they continue to perform optimally throughout their lifespan. Proper installation and regular inspections are key components of maintenance.

To extend the lifespan of these expansion joints, avoid over-tightening or stressing the rubber beyond its designed limits. Regularly inspect the joints for signs of wear, such as cracking, brittleness, or deformation, especially in areas exposed to high oil concentrations or extreme temperatures.

Cleaning is also crucial; ensure that the joints are free from oil buildup or other contaminants that could affect their performance. A clean and properly maintained oil-resistant rubber expansion joint will provide optimal vibration isolation and resistance to oil degradation.

Summary

Oil-resistant rubber expansion joints offer unmatched durability and flexibility for systems exposed to oils, fuels, and chemicals. They help to absorb vibrations, prevent leaks, and maintain system integrity in harsh industrial environments.

Our company’s new website is now live, featuring the latest product introductions. For more details, please visit https://shsjflex.com